Epoxy coatings have become increasingly popular for their durability and aesthetic appeal. However, one common issue that surfaces over time is yellowing.

This can diminish the visual appeal of surfaces, whether in homes, commercial spaces, or industrial settings. Understanding the causes of this discoloration and implementing preventive measures can extend the life and appearance of epoxy coatings.

Understanding Yellowing: What Causes It?

Yellowing in epoxy coatings is primarily caused by exposure to ultraviolet (UV) light. UV radiation breaks down the chemical structure of the epoxy, leading to a change in color. This process is gradual but can be accelerated by heat, humidity, and poor quality materials.

Another factor is the presence of certain additives in the epoxy formulation itself. Some formulations, especially those not specifically designed for UV resistance, may yellow more quickly than others. Low-quality or outdated resins can also contribute to this unwanted change in color.

The Role of UV Stabilizers

One effective way to combat yellowing is through the use of UV stabilizers. These additives absorb UV radiation and can significantly reduce the impact of sunlight on the epoxy surface. When selecting an epoxy coating, inquire about the presence of UV stabilizers in the formula.

High-quality epoxy resins with built-in UV protection not only help in maintaining color integrity but also enhance the overall durability of the coating. Investing in a premium product often pays off in the long run, saving you from frequent touch-ups or total reapplications.

Application Techniques Matter

The method of application can also influence how well an epoxy coating performs against yellowing. Ensuring a thick, even coat helps to create a protective barrier against UV light and environmental factors.

Follow the manufacturer’s guidelines for mixing and applying the epoxy. Often, applying multiple thin layers is more effective than a single thick coat. This method can ensure better curing and bonding, leading to improved resistance against yellowing.

Choosing the Right Environment for Application

The environment where you apply the epoxy plays a crucial role in its longevity. High humidity or excessively warm conditions can hinder the curing process and impact the final appearance.

Aim to work in a controlled environment with moderate temperatures and low humidity. This will facilitate proper curing and adhesion, reducing the risk of yellowing due to environmental factors.

Maintenance: Keeping Epoxy Coatings Clean

Regular maintenance goes a long way in preserving the appearance of epoxy coatings. Dirt, dust, and debris can accumulate on the surface, making yellowing more noticeable.

Cleaning should be done with mild detergents and soft cloths to avoid abrasive action. Avoid harsh chemicals that can degrade the epoxy and accelerate the yellowing process. Incorporating this simple maintenance routine can help keep surfaces looking fresh and vibrant.

Avoiding Direct Sunlight Exposure

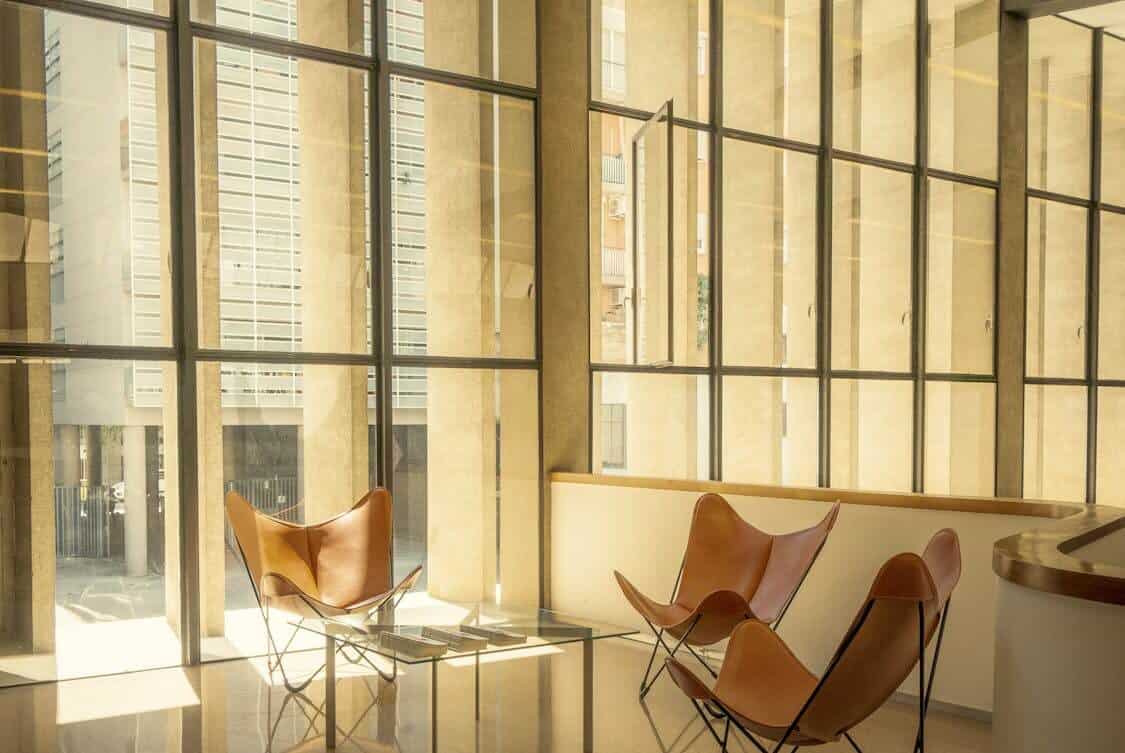

If possible, limit direct sunlight exposure to epoxy-coated surfaces. Utilizing shades, canopies, or UV-blocking films can significantly reduce the amount of UV radiation reaching the coating.

For outdoor applications, consider strategically placing furniture or plants that can offer shade. This not only helps in preserving color but can also enhance the overall aesthetic of the area.

The Impact of Temperature Fluctuations

Temperature fluctuations can affect the integrity of an epoxy coating. Extreme heat can accelerate the yellowing process, while very cold temperatures can hinder curing.

Aim to keep the temperature stable during and after the application. Avoid exposing the surface to extreme heat sources, such as direct sunlight or heaters, which can compromise the coating’s longevity.

Selecting the Right Finish

The finish of the epoxy coating can also play a role in how it reacts to UV light. Glossy finishes tend to reflect more light, which can help minimize the perception of yellowing.

On the flip side, matte finishes might absorb more UV rays, potentially leading to faster yellowing. When choosing a finish, weigh the aesthetic preferences against the practical implications of UV exposure.

For those wanting unique finishes, custom decorative quartz and metallic systems deliver vibrant color and texture options that hold up over time.

Using Topcoats for Protection

Applying a topcoat can provide an additional layer of protection against yellowing. Transparent polyurethane or acrylic topcoats can shield the underlying epoxy from UV rays, effectively extending its life.

When selecting a topcoat, make sure it is compatible with the epoxy. A mismatch might lead to adhesion issues, reducing the effectiveness of this protective layer.

Avoiding Contaminants During Application

Contaminants such as oils, dust, or moisture can compromise the adhesion of the epoxy. When applying, ensure the surface is clean and free from any foreign substances.

Consider a thorough cleaning process before you begin. The surface should be sanded or scuffed if necessary, which enhances bonding and aids in preventing yellowing from poor adhesion.

Monitoring for Damage and Taking Action

Regularly inspect epoxy-coated surfaces for signs of damage or wear. Early detection of scratches, chips, or fading can help you address issues before they lead to significant yellowing.

Prompt repair or reapplication can save time and resources in the long run. Don’t wait until the yellowing becomes a glaring problem; proactive measures can maintain the coating’s aesthetic appeal.

The Importance of Quality Materials

Investing in quality materials can make a world of difference. Cheaper epoxy formulations often lack the stabilizers and additives necessary to resist yellowing.

Research and read reviews about products before making a purchase. Sometimes, spending a little extra on high-quality materials can save you headaches down the line.

Benefits of Professional Application

While DIY projects can be fulfilling, professional application often yields superior results. Professionals are familiar with the nuances of epoxy coatings and can ensure the environment and techniques are optimal for preventing yellowing.

If you’re unsure about your skill level or the conditions in which you’ll be working, consider hiring a professional. Their expertise can ensure your investment is well-protected against yellowing.